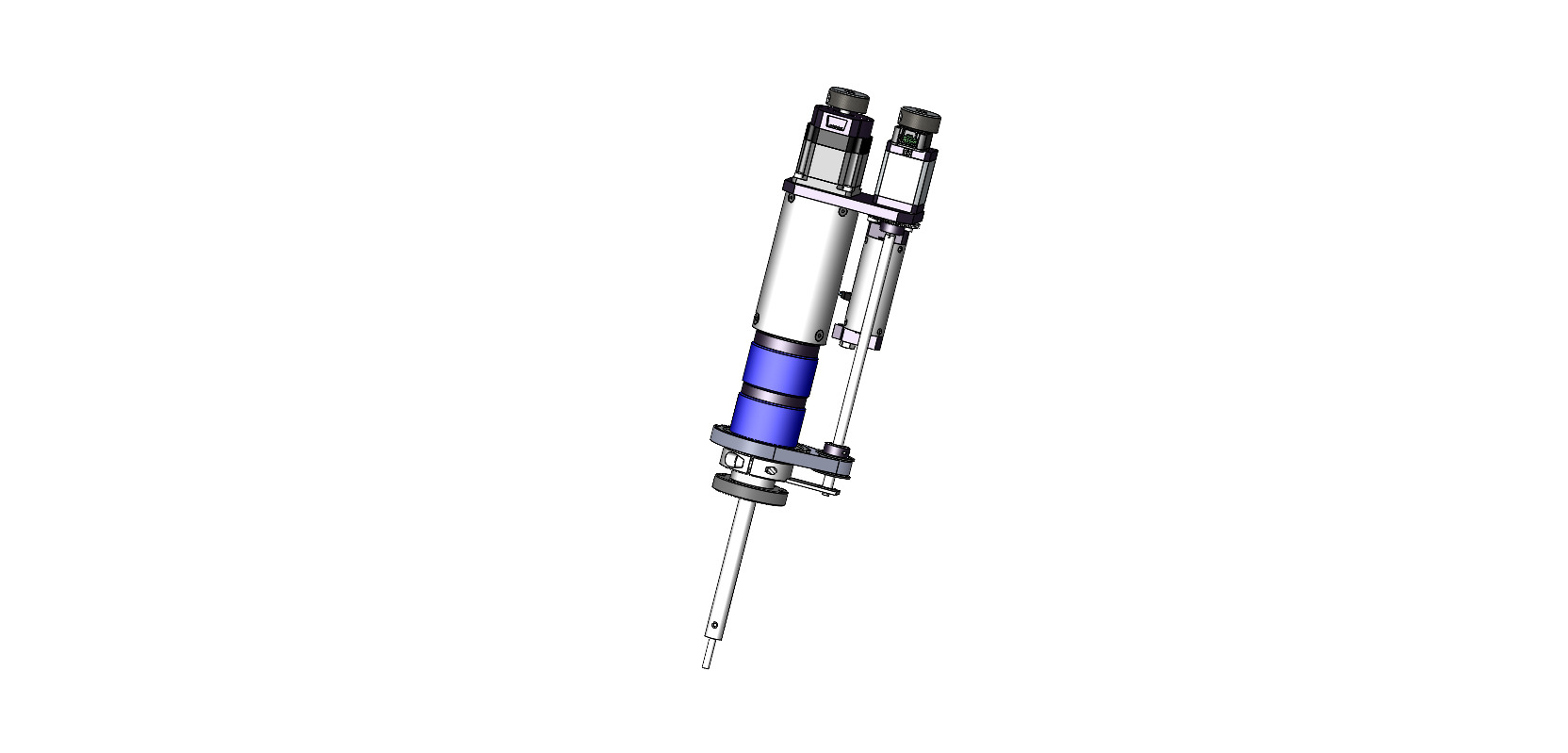

FRRMRE-275-75 – Dual Rotary Magnetically-Coupled Feedthrough

Ideal for PLD target gearboxes

- 3/4″ and 3/8″ rotating shafts

- 2.75″ O.D. mounting flange

- One or both rotary shafts can be motorized (see below)

- Manual 3/4″ adjustment diameter shaft w/position lock

- 4,000,000 revolutions before internal bearing service

- Maximum bakeout temperature: 200°C (magnetic drive removed)

- Mechanical torque limit: 150 oz/in

- Removable neodynium iron boron magnetic drive for bake-out

Stepper Motor Drive

Applications: precise positioning, positioning multiple axes at one time, computer-controlled actuation

- 200 steps per revolution

- 50 oz-in holding torque (higher torque motors available)

- Maximum speed 300 rpm

- Low inertia design

- Manual knob

- Motor controller sold separately

Synchronous Motor Drive

Applications: coarse positioning, continuous rotation

- Single speed, 72 rpm

- 2 directions

- 50 oz-in holding torque (higher torque motors available)

- Low inertia design

- Manual knob

- Motor controller sold separately

Speed Control Motor Drive

Applications: continuous rotation with variable speed, no position feedback

- Variable speed

- Switchable direction

- 5 – 95 RPM with 50 oz-in torque

- Options:

Higher torque motors

Different speed ranges - Includes Controller

Dual Axis Rotary Feedthrough, FRRMRE-275-75/SCC

(model shown here with manually operated outer shaft and

optional /SCC motor driven inner shaft)