Viewport shutters are used to shield the internal surface of a viewport from coating materials and particulate deposition during vacuum processing, helping to preserve viewport clarity and extend service life. Thermionics’ VRS Series shutters are built for ultra-high vacuum (UHV) performance, robust operation, and flexible integration into vacuum systems.

Key Features

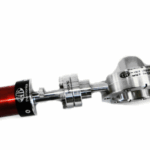

- Rotary-actuated shutter with 90° swing for full open/close operation behind standard vacuum viewports.

- FRMC-133-25 rotary feedthrough included — positive mechanical control with no stray magnetic fields and excellent vacuum integrity.

- All-metal sealed construction with stainless-steel ball bearings for long-term UHV performance.

- Integrated position lock to secure the shutter open or closed.

- Shutter cover plate protects >80% of standard viewport area, minimizing deposition on glass.

- Mounts between chamber and viewport, isolating the viewport from deposition sources.

Typical Applications

- Shielding viewports during thin film deposition, coating, and sputtering processes.

- Protecting optical sight glasses in vacuum chambers to maintain visibility and reduce cleaning cycles.

Materials & Performance

- Body / shutter material: Stainless steel (CF compatible).

- Vacuum capability: UHV performance when properly installed.

- Actuation: Rotary feedthrough driven — no pneumatics required in the standard configuration.